Tin Mining Remediation for Cornwall Business Park

Part of the challenge of assessing past tin mining activity is that its history stretches back thousands of years and yet effective records have been in existence only comparatively recently.

With the introduction of the Coal and Metalliferous Mines Regulation Act of 1872, detailed plans were produced and deposited with the Mining Records Office (MRO) following the abandonment of a tin mine.

Before this, understanding the location, orientation, or depth of workings was not possible in most cases.

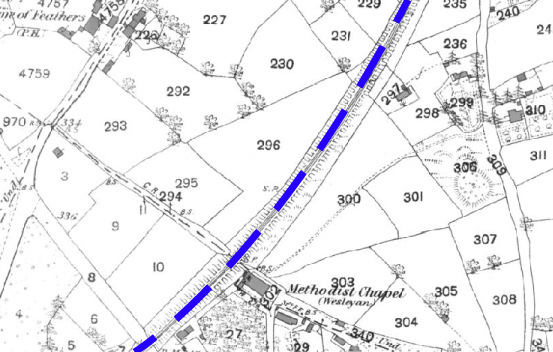

Take for example, the 1880 Country Series map above left which shows part of Redruth, Cornwall. It reveals a collection of undeveloped agricultural fields with no direct evidence of any former tin mining activity around the area called Scorrier – somewhat surprising as the name is derived from the Latin word “scoria” meaning “slag or mining waste”. Through the centre of the map (highlighted in blue) is the main line of the Great Western Railway, which was built in the mid 19th Century, well after the majority of the mining took place in the area.

Scorrier sits over a dense network of subterranean mine shafts that famously opened up a 300ft hole and demolished a patio close to a bungalow in 2016. It was part of the North Downs Mine complex that between 1862 and 1897, produced significant quantities of copper ore and arsenopyrite and in the early 1900’s, smaller amounts of black tin, tin and tungsten.

Old maps provide just a snapshot of what’s actually there, which is highlighted by the above map on the right. The red hatched areas and dashed red lines all indicate mine workings that our team of Geologists have identified during a site investigation on the boundary between the development and the railway to the east.

A Honeycomb of Shafts Revealed

The land was granted planning permission for a new business and biotech park with 23 industrial plots set within 35 acres of land, directly adjacent to the railway linking Penzance to London.

We undertook an initial desktop mining report which studied all of the available archive material. This indicated the presence of an engine house located within the central portion of the site, with extensive underground mine workings recorded on the mine plan and only a handful of mine shafts. This is quite typical for post-1872 records and it was highly likely that significant unrecorded mine workings would be present onsite.

We subsequently carried out a site investigation and discovered multiple unrecorded shallow workings and mine shafts. It was clear that these would need to be remediated to make the site safe and to future-proof the proposed development.

Built on our expertise and understanding of the structure of these informal workings, we designed and oversaw the remediation of the tin mining features. During the course of the groundworks, 114 mine shafts and surface workings were secured by installing mass concrete plugs which provides a long term solution in mitigating against mining subsidence risk.

Reducing Tin Mining Impact to Infrastructure

There was also the added complexity of mining features observed very close to the boundary between the site and the railway. In these situations, Network Rail must be consulted prior to commencement.

Given the extensive footprint of Cornish mining, it is inevitable that it could impact existing infrastructure, quite often of critical national importance. We saw how the line damage at Dawlish in Devon from coastal flooding effectively severed rail connections to Cornwall from the rest of the country and a mine shaft collapse would have been of a similar magnitude.

We have extensive experience in dealing with mining features next to railways. Prior to any work being undertaken onsite, Network Rail must have an appointed CEM (Contractors Engineering Manager) and CRE (Contractors Responsible Engineer) for the duration of the works. This is Network Rail’s own set of standards to ensure competent persons are undertaking the works.

In line with this, we delivered a compliant, detailed method statement and risk assessment. This outlined the required safe working procedure for investigating and remediating tin mining features adjacent to a live railway line.

We followed this approach on site meticulously, which enabled the development to safely continue without the risk of tin mining subsidence affecting the construction or end use of the site. In addition to the mine shafts, the site needed contaminated land remediation, over ground electricity cable diversions, Japanese Knotweed removal, on-site road and services infrastructure and off site road and bridge improvements, as well as the refurbishment of a listed Cornish tin mining engine house.

Securing the Site for Cornish Jobs

Today, the 144,000 square foot Cornwall Business Park is now home to thriving enterprises and major brands including Jaguar Land Rover – delivering much needed jobs in the local area. We were delighted to play our part in securing the integrity of the groundworks from the legacy of the tin mining that forms a honeycomb of tunnels below the surface.

Ward Williams Associates (WWA) was appointed as Project Managers, Quantity Surveyors and Principal Designer for the site, who subcontracted via Cormac Consulting. They recognised Groundsure not only for their expertise in mining geology, shaft inspection and remediation, but also the competence to safeguard the adjacent infrastructure and workforce to comply with Network Rail’s stringent requirements.

For more information about Groundsure’s range of site investigation services, visit www.groundsure.com/mining or call 01273 257 755 or email info@groundsure.com

For more articles, blogs and events about tin mining and remediation up to date with Groundsure on Twitter.

References

https://www.mindat.org/loc-194323.html

https://premierconstructionnews.com/2016/08/12/hallenbeagle/

https://cornwallbusinesspark.co.uk/

https://www.dailymail.co.uk/news/article-3491246/Amazing-pictures-300ft-Cornish-mineshaft-captured-drone.html

Date:

Feb 2, 2022

Author:

Ryan Hitchens